Winterwarm Radiant Heating & Air Conditioning

Winterwarm Radiant Heating & Air Conditioning Hampshire

Manufacturing Facility, Aldershot

Workshop Size – 3,078m²

Background:

Based in Aldershot, Hampshire and founded in the late 1970’s, this client is a specialist supplier of printed pens and complementary promotional products. After expanding the company year on year, they decided to merge all of their sites across Aldershot into one premises.

Industrial Heaters have been providing services to this client since 2010 including installation work, routine maintenance, and a quick response to any breakdowns reported. Prior to moving into the building, we were contacted to provide a proposal and specification to supply and install suitable heating and air conditioning throughout their new manufacturing and storage facilities to be carried out over two phases.

Phase 1 – Heating

Heating Solution:

Our surveyor specified different heating system solutions suited to different process areas in the manufacturing areas and storage facilities on site. We installed five Reznor gas fired double linear radiant tube heaters above the manufacturing areas. The heaters provide an efficient and even spread of heat throughout this area.

The heating is controlled by Smartcom digital controllers which allow the monitoring running times.

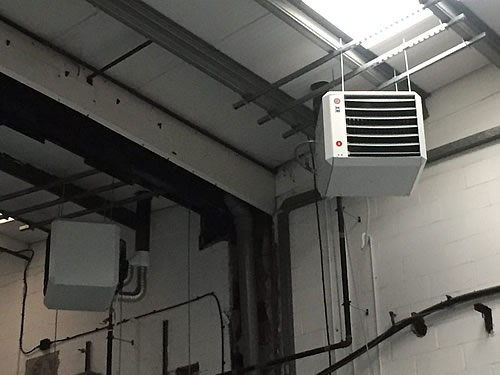

In the storage facilities, we installed two Winterwarm fully modulating gas fired suspended heaters, combined with twelve destratification fans. Each heater is controlled by a Multitherm controller.

Heating Result:

Warm air heating provides total warmth to a large area. Destratification fans are ideally installed alongside warm air heating and are specifically designed to reduce the temperature differential between the roof space and the floor level. This also has the additional benefit of reducing fuel consumption.

By heating the manufacturing areas with radiant heating which produces direct localised heat, the customer will see a cost saving compared to attempting to heat the whole area with warm air.

The controllers provide optimised start, frost protection and PIN facility to stop unauthorised use and consequent fuel wastage.

Air Conditioning Solution:

Together with our supplier, we selected MHI systems that would perform efficiently and effectively in production rooms, laboratories, a canteen, meeting rooms, a server room and offices.

22 Mitsubishi ceiling cassette air conditioning systems were installed. Each system had to be carefully selected to suit the installation.

Our engineers worked alongside other trades during the re-fit process.

Air Conditioning Result:

The main benefit to installing single splits is that each system is completely independent from each other, this allows for different temperatures to be achieved in each area. Also, in the event of a fault, only one area is affected.

In order to maintain the units looking as aesthetically pleasing as possible the units are run on condensate pumps to avoid drains being visable.

Previous Case Study:

Next Case Study: